Minimize costs and downtime when de-scaling with ultrasonics

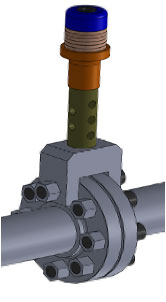

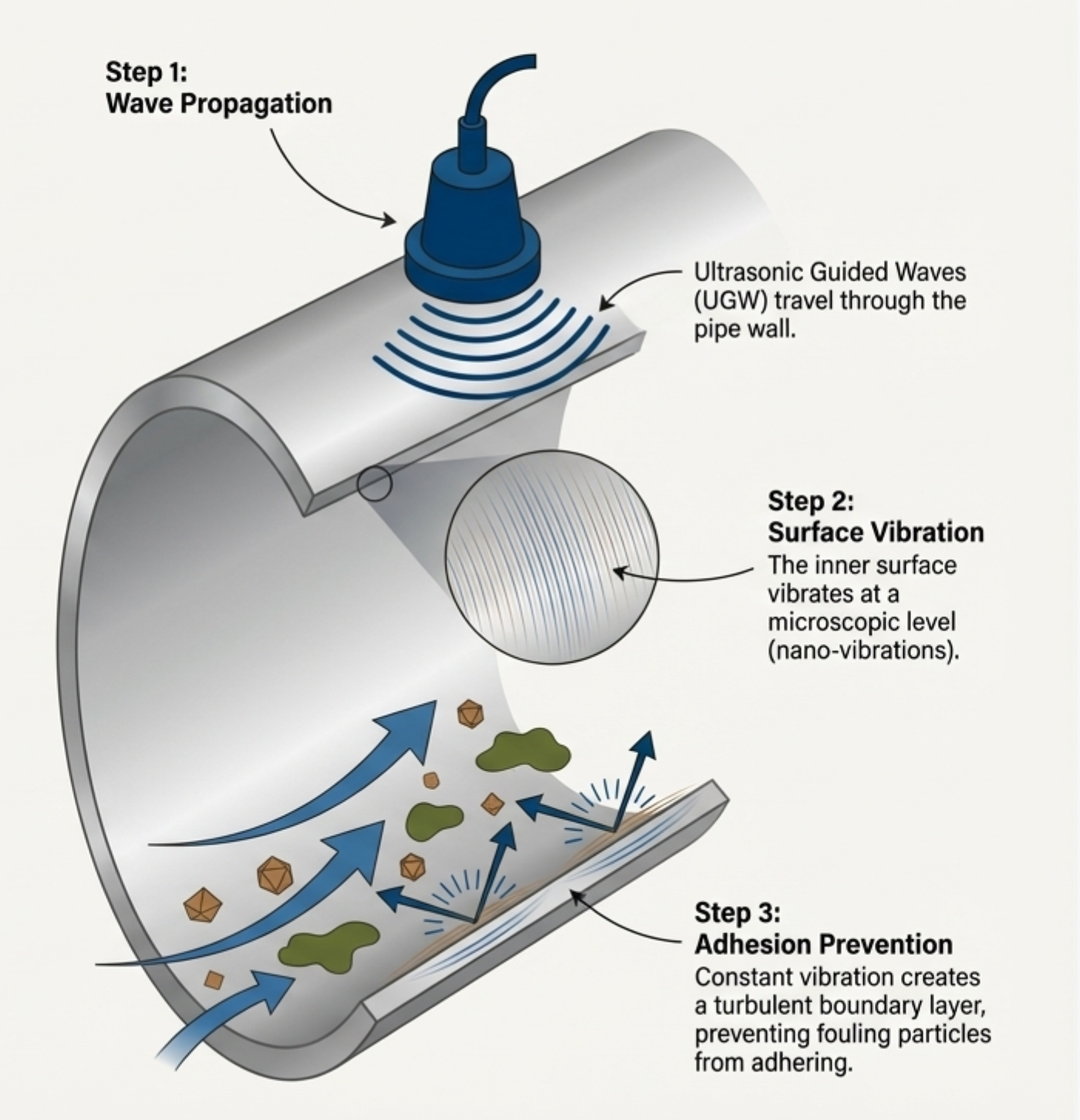

Our MMM ultrasonic transducers can minimize significant operating and maintenance expenses by breaking down and preventing fouling and scale build-up in heat exchangers and other high-tech, sensitive and complex metal parts. What we offer is radical and unmatched innovation.

£170M

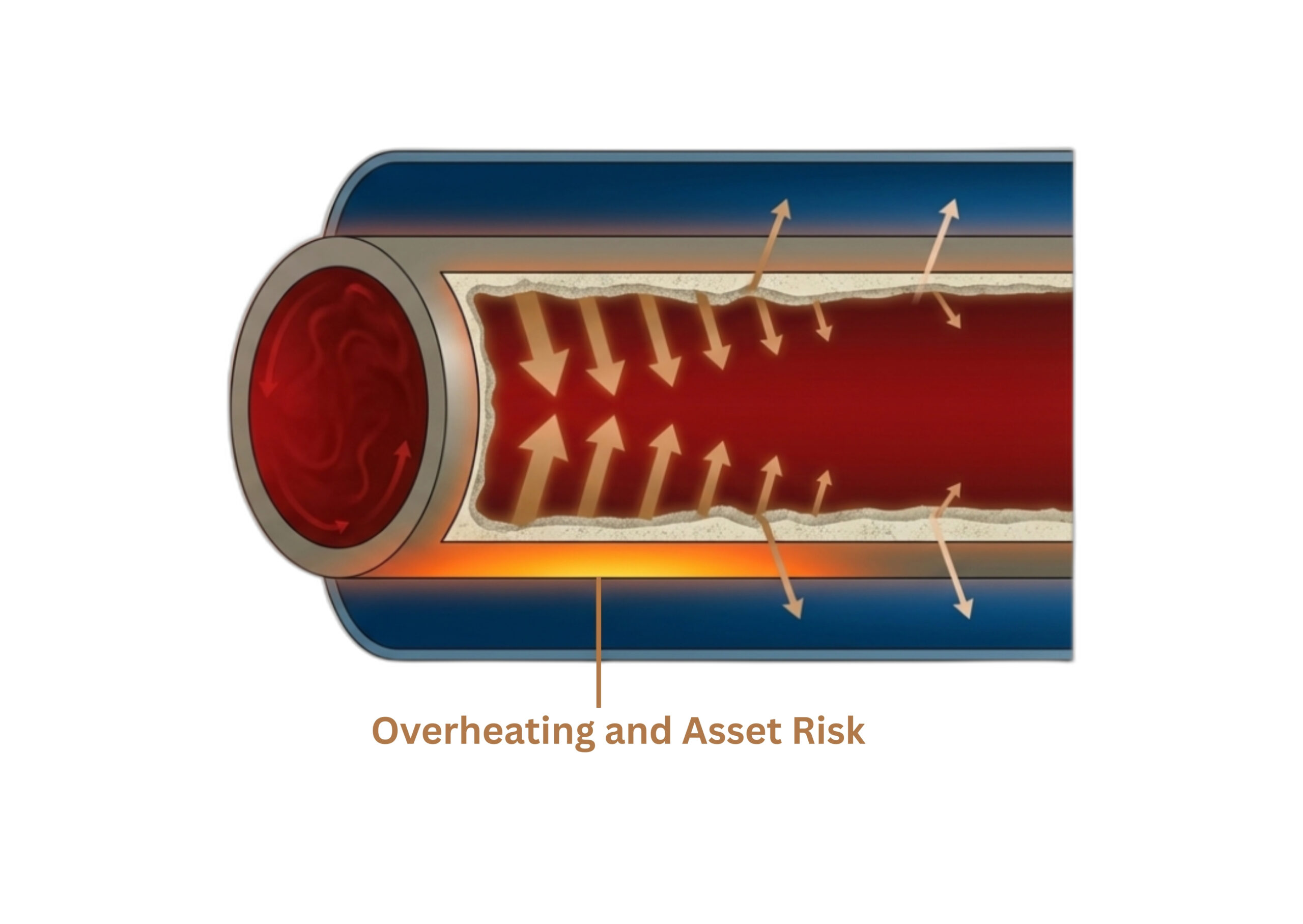

A single refinery study estimated annual excess fuel costs due to fouling at ~$170 Million at global prices.

Ultrasonic scale prevention extends equipment operational life by 25-30%.

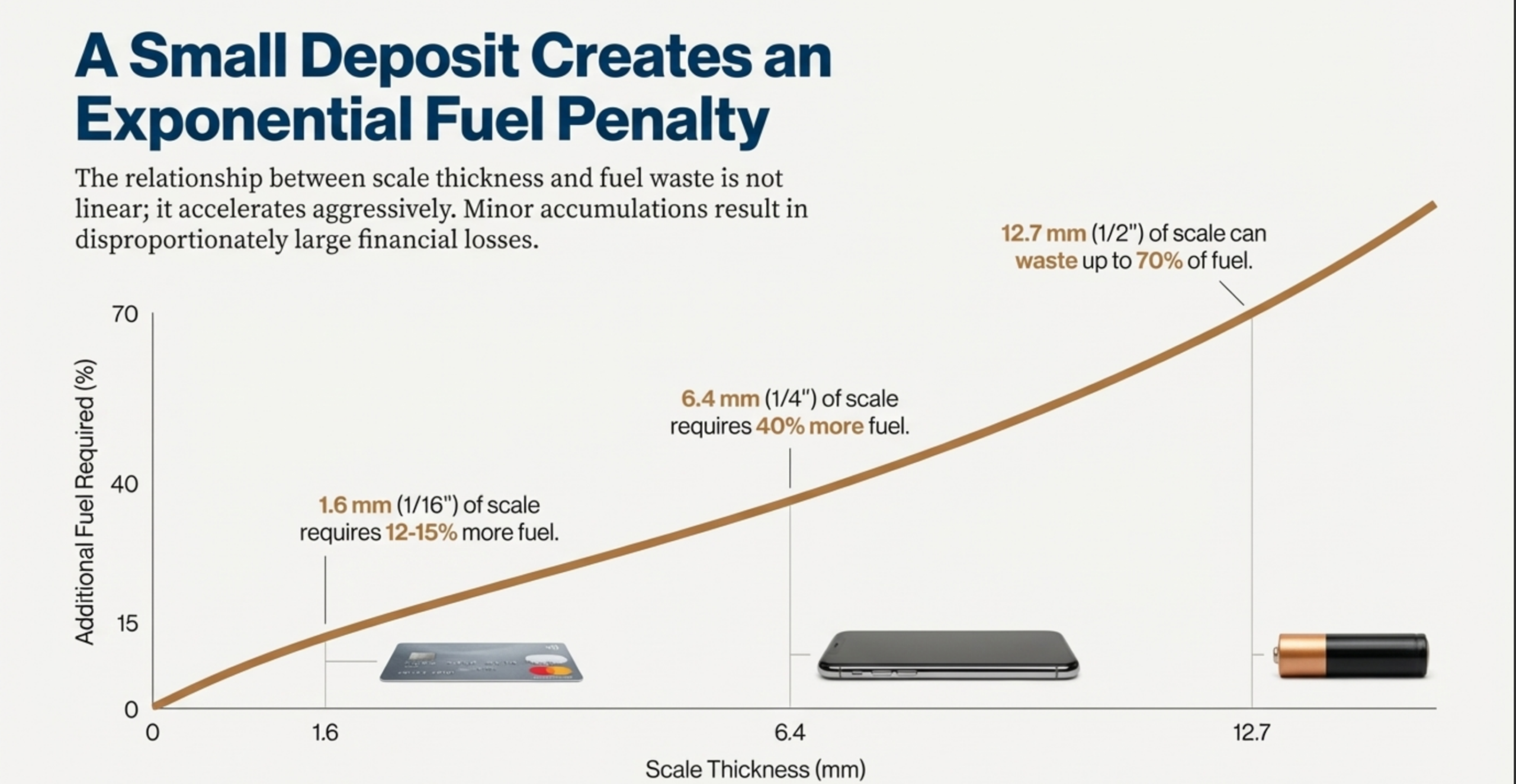

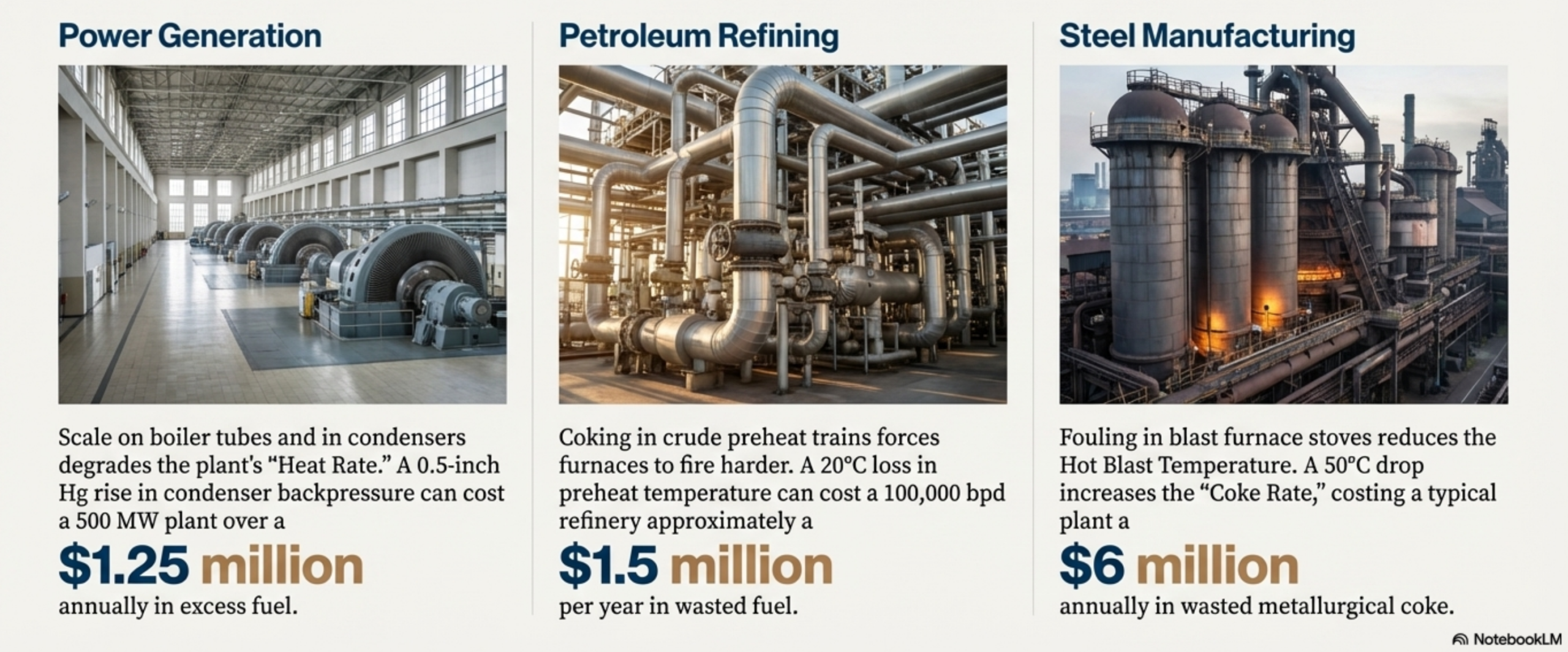

No Critical Industry is Immune to the Efficiency Tax

Fouling imposes severe, quantifiable penalties across all heavy industries, threatening energy security, supply chains, and economic output

Scale prevention is a measurable and financially viable decarbonization strategy

MMM INDUSTRIES

Advantages of MMM Technology for Descaling

Minimize operational downtime to cleaning processing systems

Reduce capital expenditures by extending equipment lifespan

Relieve and prevent stress on metal parts

Sustained peak efficiency: Increase energy efficiency of the system by increasing the output flow

Zero waste, chemical-free and low energy consumption

Safe, non-invasive, external clamp-on system - easily installed