MMM INDUSTRIES

MMM Technology

With Multifrequency, Multimode, Modulated Sonic & Ultrasonic Technology, you can achieve complete, uniform and homogenous agitation of large solid masses and liquids unrivalled on the market. Complete resonance is obtained throughout any small, large and arbitrary shaped object.

Our system allows for precise amplitude-frequency modulation of ultrasonic effects and obtains optimal results for complex material processing and cleaning.

MMM INDUSTRIES

Redefining Ultrasonics

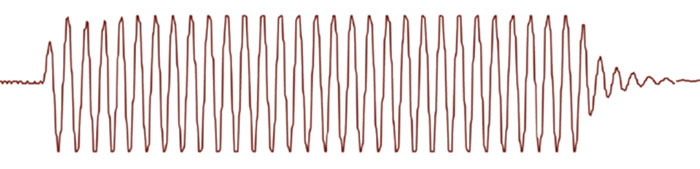

Traditional ultrasonic actuators or transducers available on the market today oscillate in a relatively simple constant-frequency, contraction-extension vibrating mode. They are designed to satisfy pre-defined and fixed resonant conditions. This type of technology has limited application possibilities: it can be applied for the treatment of relatively simple and regularly shaped objects.

To achieve maximal efficiency with traditional ultrasonic technology, all oscillating bodies must resonate at the same frequency and have the same natural, resonant frequency throughout the object. However, when the object is larger or more complex, the more complex and diverse the natural resonant frequencies become. Therefore, applying a single operating frequency like traditional systems do leads to poor results, mainly because of the creation of standing waves. Moreover, the depth and amplitude of traditional fixed frequency ultrasonic excitation is relatively low when compared to our MMM method. For this reason, the corresponding efficiency and speed of ultrasonic cleaning and liquids processing is much lower (up to a factor of 10!).

In contrast, MPI developed the proprietary Multifrequency, Multimode, Modulated Sonic & Ultrasonic system (MMM) which generates wide-band sonic and ultrasonic oscillations, from the infrasonic up to the MHz frequency domain. These oscillations propagate through any arbitrarily shaped and complex solid structures. These include pipes, heavy and very thick metal containers, pressurized reservoirs, very thick metal walls of autoclaves.

Generating multimode mechanical oscillations avoids the creation of stationary or standing waves which are typically produced by traditional ultrasonic systems. MMM technology provides the user with much greater freedom of control, regulation and programming over all vibration, frequency and power parameters.

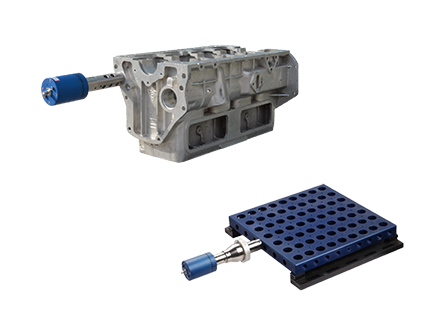

Any complex part can be vibrated

with MMM technology

Our patented Multi-frequency, Multimode, Modulated Sonic & Ultrasonic actuators operate at certain pre-defined and optimal resonant frequencies. This achieves a completely uniform and well distributed vibrational agitation. This, in combination with a continuously applied frequency and amplitude modulation, agitates and excites many resonant modes, harmonics and subharmonics of any large or complex object, benefitting a large number of applications and technologies.

Ultrasonic Cleaning Generations ahead!

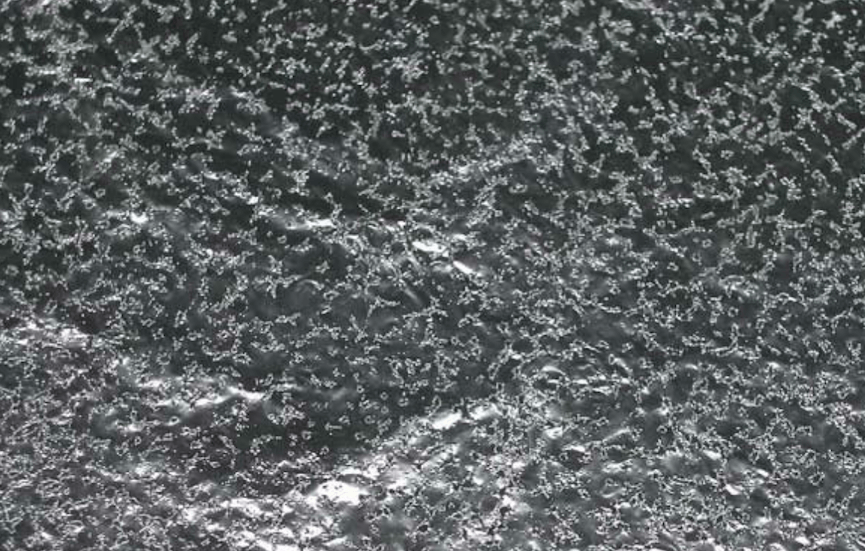

A new aluminum foil was placed into our ultrasonic bath and held the foil for approx. 5 - 10 seconds. Look at the result! A perfectly, uniformly perforated aluminum foil. There is simply no comparison with any other conventional ultrasonic cleaning machine! Independent of the water level and depth, the process is also extremely efficient (>95%), which will leads to considerable energy savings. Find out all the details here.

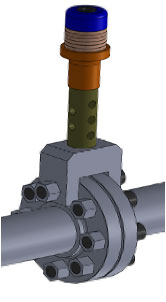

Simple clamp-on systems

We can attach the device in multiple ways.

- External clamp-on system

- External screw/weld/bond – on

- Internal submersible sonorod transducers.

Adaptive Clamp

Clamp on MMM system

Old fashioned scale removal with

mechanical vibration

Novel MMM approach to descaling

and stress relief

MMM INDUSTRIES

What Makes Our MMM Systems Unique

By synchronously exciting many vibrating modes in solids and liquids, including harmonics and sub harmonics, MMM systems produce high intensity and high efficiency sonic and ultrasonic vibrations that are uniform, homogenous and repeatable. Our MMM system offers fine control and excellent repeatability through to its programmable interface. The active power produced ranges from less than 100 W up to several kW.

- MMM sonic and ultrasonic vibrations can be excited in any heavy-duty conditions, producing pulse-repetitive, phase, frequency and amplitude-modulated bulk-wave-excitation covering and sweeping an extremely wide frequency band.

- MMM sonic and ultrasonic driving creates a unique, uniform, and homogenous distribution of acoustical activity on a surface and inside of the vibrating system, while avoiding the creation of stationary and standing waves, so that the whole vibrating system is fully agitated.

- Multi-frequency ultrasonic structural excitation is ideal for agitating arbitrary shaped liquid and solid masses at arbitrary distances and placed on pipes/pipelines, at any temperature, while maintaining optimum efficiency of electrical to acoustic energy conversion.

Downloadable files:

What makes our MMM systems unique - preventive descaling and cleaning of heat exchangers

Descaling heat exchangers with MMM (PowerPoint)

Cleaning of oil & gas pipelines

Ultrasonic descaling and stress relief (PowerPoint)

Basic elements of MMM systems and how they operate

Important facts about MMM technology

European patent application

Additional resources for all MMM applications: https://www.mastersonics.com/documents/mmm_applications/Descaling+Stress%20Relief/